Compression Molding Presses

Compression Molding, Composites Molding, & Laminating

What Is A Compression Press?

A compression press, also known as a compression molding machine, is a type of hydraulic press that is used to mold fiberglass and composite parts such as boards, composite defense, aerospace products, friction materials, prepregs, silicons, thermosets, laminate boards, and honeycomb panels. Compression molding presses are utilized in a variety of industries such as aerospace, consumer products, industrial, and automotive.

Savage’s composite presses, custom-designed molding and laminating presses support a wide range of environments, from lab and R&D to production lines and testing facilities.

Up-Acting Compression Molding Presses

The upwards pressing action prevents oil from ever contacting hot surfaces and prevents contamination of sensitive parts.

This 170-ton Up-Acting Two-Opening Press (left) has four (4) 43″ x 40″ heated platens and is used to compress dry sponges. By compacting the base material of their product, this compression molding machine allows our customer to dramatically increase their freight volume per shipment.

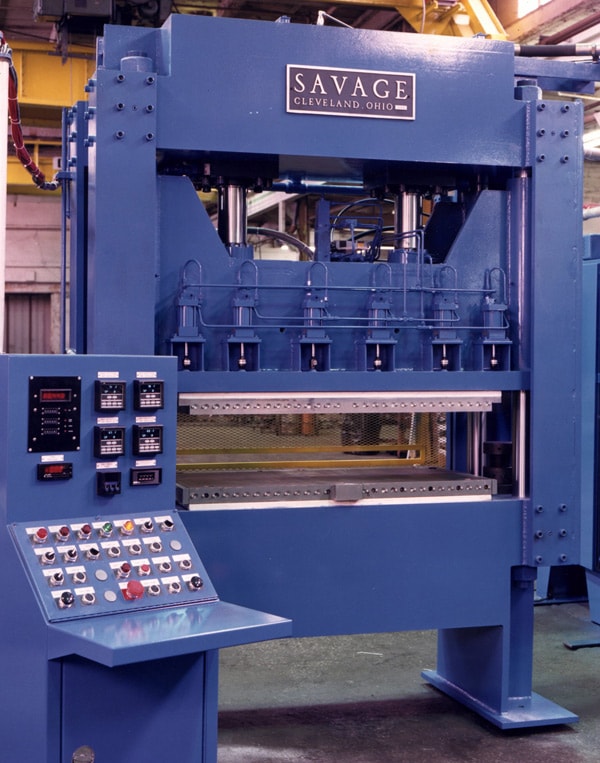

Down-Acting Compression Molding Presses

This 100-ton Down-Acting model (left) is used 52″ x 30″ electrically heated platens and individual zone controllers with SCR control to emboss the designs into wet ceiling tile board for Armstrong

Catalog Information on Down-Acting Presses

Laminating and Bonding Presses

Available in both up-acting and down-acting models, these compression molding machines have heated platens and are equipped with large beds to handle oversized products.

This 230-ton Bonding Press (left) is installed at the Mitsubishi Electric Power Products, Inc. factory in Memphis.

Catalog Information on Laminating and Bonding Presses

Multi-Opening Presses

Multi-opening presses allow you to bond or laminate multiple products during the same dwell time, all without increasing your press tonnage.

This 500-ton Multi-Opening, Up-Acting Bonding Press (left) has four (4) 168″ x 84″ Oil Heated Platens for manufacturing honeycomb panels.

Catalog Information on Multi-Opening Presses

Compression Molding Lab Presses

The Compression Molding Lab Press offers the whisper-quiet operation, smaller bed sizes, and individualized, sophisticated control options that are necessary for R&D environments.

This 50 ton Lab Press (left) performs thermoplastic composite molding of medical implants.

Catalog Information on Lab Presses

Available Frame Types:

- Up-Acting Compression Molding Presses

- Down-Acting Compression Molding Presses

- Laminating and Bonding Presses

- Multi-Opening Presses

- Compression Molding Lab Presses

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Motion and Temperature Controls

Available in 2-Post and 4- Post, Down-Acting, and Up-Acting variants, as well as a large bed, rack-and-gear-guided presses.

Laminating and Bonding presses can have multiple openings for simultaneous lamination on multiple pieces.

Presses are available either hot, cold, or both. Available with temperature-controlled heated platens or with temperature controls for independently heated tools. Individual zone controllers are provided on systems using up to eight (8) temperature-controlled lops. More zones often use on-screen temperature control. Platens can be electrically heated or fluid-heated with hot oil or steam.

- Temperature controls for hot or cold

- Up to 8 individually-controlled temperature zones

- Electrical or heated oil or steam, depending on application requirements

- User interface control options – pushbutton panels, touchscreens

- Thermal fluid heating units with remote temperature control adjustments and actual process temperature integrated into the touchscreen

- Made in the USA

Savage does not stock catalog sizes. Each press is engineered to your specifications to perform your job at maximum efficiency.

Industries Served

- Aerospace

- Automotive

- Chemicals

- Composites

- Consumer Goods

- Flooring

- Laminates

- Medical Devices

- Military & Defense

- Polymers & Plastics

- Rubber

- SMC / Sheet Molding Compound

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED IN ANY OF OUR PRESSES.

CONTACT US NOW to Discuss Your Application